Researches and Discoveries in Kent

Contributions to the next volume are welcome. See the guidance for contributors and contact Editor Jason Mazzocchi. Also see the guidance for peer review.

Search page

Search within this page here, search the collection page or search the website.

Churchgoing in the Cradle of English Christianity: Kentish Evidence from the 16th to the 20th Centuries

Reviews

Researches and Discoveries in Kent

RESEARCHES AND DISCOVERIES IN KENT

traces of prehistoric and romano-british occupation at barton mill, canterbury

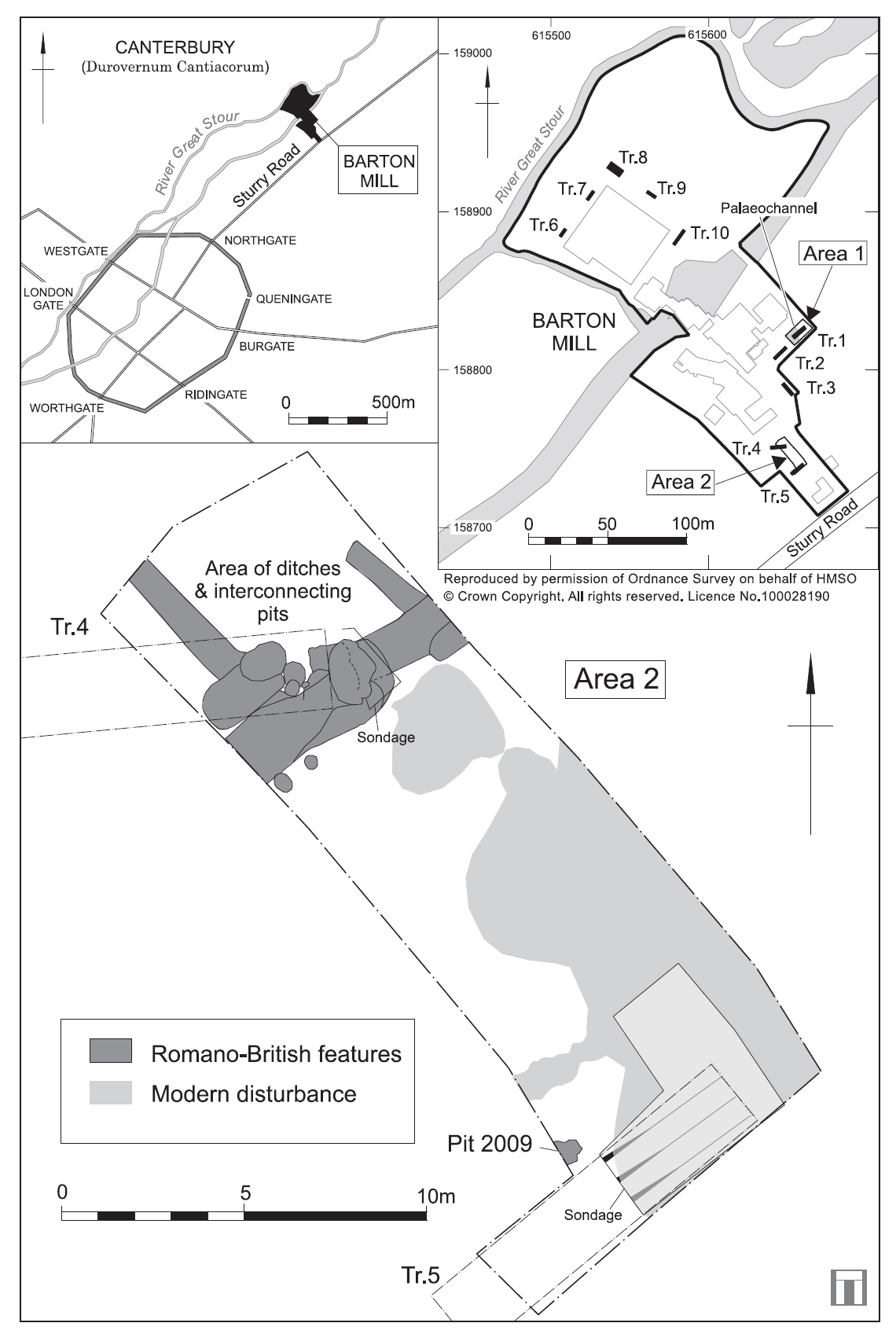

Investigations by Wessex Archaeology at Barton Mill, Canterbury (NGR 615600 158850) (Fig. 1: Areas 1-2) revealed traces of Neolithic activity and part of a probable Romano-British farmstead.1 The site, which until recently was occupied by mill buildings, offices and warehousing, is located within the Stour Valley, approximately 1 km to the north-east of the City’s Northgate and to the west of a major Roman road, whose course runs towards the Isle of Thanet. Given the extent of the site and its proximity to the Great Stour and the mill stream, it was not surprising that alluviated deposits, relict silted channels and a remnant of a gravel island (eyot) were encountered in the evaluation (Trenches 7, 8 and 10)2 and the presence of peat and organic rich deposits would suggest a typical shift from active channel to back swamp conditions.3 Unfortunately no anthropological evidence was encountered during these investigations.4 Part of a north-south aligned palaeochannel identified within the east end of the Area 1 excavation trench (Fig. 1), which was of undetermined width and depth, produced no direct dating evidence, although it is thought to have silted up by the Roman period.

The evaluation (Trench 1) had identified a possible remnant of an ancient land surface on river terrace gravel deposits that had been preserved beneath alluvium.5 An Early Neolithic flint scatter, possibly in situ and indicating small-scale occupation, was associated with this horizon. However, during the excavation phase (Area 1) the continuation of this horizon could not be traced, due almost certainly to modern truncation.

Evaluation layer 73 contained a small (161 pieces) cluster of Early Neolithic flintwork, mostly waste from the production of narrow flakes and blades, some of which were struck from the same core, although only one refit was noted.6 Three probable axe-thinning flakes and five miscellaneous retouched flakes were also recovered. Burnt utilised pieces provide indirect evidence for hearths. The occurrence of edge damage and incomplete reduction sequences indicate that this was a dump of quite fresh material rather than in situ working. The low numbers of residual flintwork across the site could suggest that the deposit in layer 73 represents discard from a small-scale and short lived period of occupation. It is perhaps not surprising to find such evidence close to the edge of a major river.

Within Area 2 (centred on evaluation Trenches 4-5) pits, three postholes and four ditches (Fig. 1) attributed to a Romano-British date may represent part of a small-scale settlement/farmstead adjacent to the course of the Roman road that runs between Canterbury, the Isle of Thanet and the Saxon Shore fort at Reculver (Regulbium), aligned approximately on the present Sturry Road.7 One of the ditches was cut by some pits indicating more than one phase of activity. Artefactual remains were generally quite poor but did include a few sherds of Romano-British greyware.8 One of the pits (2009) contained the degraded remains of wheat and barley grains, as well as a single oat grain.9 The identification of this grain as free-threshing wheat and the presence of a single seed of stinking mayweed, would support the suggested Romano-British date, although a later date (Saxon/Medieval) would be equally possible.10

The general paucity of artefactual remains made precise dating of the settlement features difficult other than to state a broad Romano-British date, while no further evidence of possible late Iron Age activity was found.11 Likewise, while the charred plant remains could suggest a Saxon or Medieval date, there is no artefactual evidence to corroborate this.

Given the proximity of the site to the River Stour it is perhaps not surprising that traces of prehistoric activity were found in the investigations as such locations would provide resources and a suitable location for settlement as indicated by the lithic evidence. The traces of Romano-British settlement, with possible earlier origins and later developments are again not surprising given the proximity to Roman Canterbury (Durovernum) and this adds to an emerging picture of native settlements in this vicinity.12

Acknowledgements

Wessex Archaeology would like to thank Duncan Hawkins (CgMs Consulting Ltd) and Richard Cross (Archaeological Officer for the City of Canterbury) for their assistance and advice, and Weston Homes Plc for funding the analysis and publication. The project was directed by Kevin Ritchie and Jonathan Nowell assisted by Lorraine Mepham, Chris Stevens, Alistair Barclay and Julie Gardiner.

The archive will be deposited with Canterbury City Museum (61260).

k. ritchie and j. nowell

1 Wessex Archaeology, 2006, ‘Barton Mill, Canterbury, Kent’, unpubl. post-excavation assessment report 61260.01; Canterbury Archaeological Trust, 2004, ‘An Archaeological evaluation at Barton Mill and Barton Mill Road, Sturry Road, Canterbury’, unpubl. CAT Report 2004/49.

2 CAT, op. cit., see note 1, 18-19.

3 Ibid., see note 1, 28.

4 Ibid., see note 1, 35.

5 Ibid., see note 1, 11-12.

6 Beadsmoore in CAT, op. cit., see note 1, 22-7 and table 2.

7 Blagg, T.F.C., 1982, ‘Roman Kent’, in Archaeology in Kent to AD 1500 (ed. P.E. Leach), CBA Res. Rep., 48, 51-60.

8 WA, op. cit., see note 1, 8 and table 1.

9 WA , op. cit., see note 1, 8.

10 WA, op. cit., see note 1, 10.

11 CAT, op. cit., see note 1, 21.

12 Boden, D.C., 2004, ‘Shelford Farm Estate, Broadoak Road, Canterbury, Kent. Archaeological excavation on the site of the Eastern Attenuation Pond. Stratigraphic Report’, unpubl. CAT client report.

latin rumen ‘gullet’ and the name of romney

New Romney (TR 0624), two miles east of Old Romney and a mile from the sea, is one of Kipling’s ‘ports of stranded pride’. It has a long history, with a recorded church in the eighth century and a mint in the tenth. If New Romney is old, so too is its name, which has been amongst the enigmas of Kent, defying proper explanation.

The forms are thus. The town appears as Rumenea in the Anglo-Saxon Chronicle for 1052 and as Romenel in Domesday. It lay by a channel of water (on the course of the later Rhee Wall) which is recorded as Rumenea in 895 and Rumenesea in 924, where ea is Old English for ‘river’. Scholars used to link the first element with Old English rum ‘spacious’, as with Romford ‘wide ford’ in Essex or Romiley ‘wide clearing’ in Greater Manchester. Yet that does not explain -en-. The English Place-Name Society now hesitantly explains it from an otherwise unknown English personal name ‘Rumen’, with a meaning ‘river of a person called Rumen’.1 But that suffers from an obvious disadvantage. There is not a shred of other evidence for this personal name. Let us try another approach, referring to words that are known, instead of those that are not.

Now, Latin rumen, though often translated ‘gullet’, really means ‘an enlargement of the gullet in which food is stored, the first “stomach” of ruminants’, those clean beasts that chew the cud. It was borrowed as rhumen by late medieval Welsh in the sense ‘belly, paunch’, and appears on maps of Wales at places called Rhos-y-rhumen ‘moor of the belly-shaped hill’. One of these is near Llanllyfni (SH 4751), south of Caernarfon, the other by Llanuwchllyn (SH 8730), west of Bala Lake.2 If Latin rumen gave a place-name element in late mediaeval Wales, it could have done the same in Roman Britain, where Latin was far more widely spoken. The old mouth of the Rother (today a mere ditch south of Romney church) was a major haven for shipping from early Anglo-Saxon times.3 So there would be nothing surprising if Roman mariners had called it Rumen ‘The Gullet’. The Oxford English Dictionary’s entry for gullet notes how the English word was used from the sixteenth century to mean ‘water channel; a narrow, deep passage through which a stream flows; a strait, estuary, river mouth, etc.’. The English word gut has also meant ‘a narrow channel of water’ from that date. If English seamen could speak of a ‘gullet’, so could Roman ones, applying rumen ‘gullet’ to a river mouth or estuary useful as a landmark or landfall.

One may add that, although most British-Latin toponyms are Celtic (like Londinium, Dubris ‘waters’ or Dover, or Regulbium ‘great head-land’ or Reculver), some are Latin. Examples occur from Herculis Promontorium (Hartland Point, Devon) in the South-West to Ripa Alta ‘high bank’ (Tarbat Ness, Ross and Cromarty) in Scotland. Aust, at the English end of the Severn Bridge, shows such a name surviving to this day. Professor Coates of the University of Western England, who discusses this and other Latin toponyms surviving in modern Britain, argues as well that the ancient name of Lindisfarne in Northumberland was Latin Medicata ‘healing island’, perhaps because it was rich in herbs.4 Latin-speaking sailors and traders gave Latin names to coastal features throughout the Roman Empire, including Lampas ‘lighthouses’ in the Crimea (one of which stood at the town of Maliy Mayak, Russian for ‘little lighthouse’).5 If Rumen were another such seafaring term, it would be no surprise. It is also likely that Latin Rumen ‘The Gullet’ as a name for the Rother’s former estuary was known to the Saxons early on, perhaps even before the invasion period, as was surely the case with Racuulfe or Reculver.6 It would be a poor Saxon pirate who could not name the forts, creeks and estuaries of Roman Britain.

If, then, Old English Rumenea and Rumenesea are correctly understood as ‘river of the Rumen, river of the “Gullet”’, the channel that gave its name to New Romney and to Romney Marsh as a whole, we catch a glimpse of ancient Kent. As the British-Latin name for the estuary of the Rother, Rumen implies this reach of water resembled the bag or stomach in the gullet of a cow, deer, goat or sheep. It would have been a broad natural harbour opening out from a narrows. The Roman ships that entered and left it were perhaps engaged in trade, as would be natural for a part of Britain close to Gaul. If so, that may relate to finds of Roman objects at Lydd and elsewhere near Romney. The name was also familiar enough to survive the loss of Britain in the fifth century and recur in Old English, the Rumen perhaps being known as such to Anglo-Saxon pirates at an early date.

In short, if Romney’s name derives from Latin rumen ‘gullet’ plus Old English ea ‘river’, it casts light on its history. It reveals a toponym surviving from Roman Britain into Anglo-Saxon and modern England. It gives a perception of this place in the salty language of Roman mariners, suggesting it was a safe anchorage, perhaps with both military and commercial importance. It thus extends the history of Romney back from the Anglo-Saxon period into Roman times: a matter of pride for any port, stranded or not.

andrew breeze

1 The Cambridge Dictionary of English Place-Names, ed. V. E. Watts (Cambridge, 2004), 507.

2 Geiriadur Prifysgol Cymru: A Dictionary of the Welsh Language (Caerdydd, 1950-2002), 3104.

3 M.W. Beresford and J.K.S. St Joseph, Medieval England: An Aerial Survey (Cambridge, 1979), 206-7.

4 Richard Coates and Andrew Breeze, Celtic Voices, English Places (Stamford, 2000), 54-7, 241-2.

5 Alexei Solopov, ‘The Imperial Context of Place-Names in Roman Britain’, Journal of the English Place-Name Society, xxxvii (2005), 5-18.

6 K. H. Jackson, Language and History in Early Britain (Edinburgh, 1953), 558-61.

some notes on the technical details of mills provided by the kilwardby survey

The Kilwardby survey of 1273-4 (see pp. 107-28) contains a con-siderable amount of technical detail regarding the operation and repair of watermills and windmills on the archbishop’s demesne manors. The writer was invited to compile some notes on this material and these are set out below. By the 1270s windmills had been in operation in Kent for nearly a century and it is therefore not surprising that some specific references to this newer type of mill are included in Kilwardby. (See also the following short article on Kent’s earliest windmills, pp. 377-78).

Picks

‘ … the repair of the picks’ [Saltwood]

‘ … and 1 pick bought’ [Maidstone, East Mill]

‘ … for 1 talc of steel for the picks’ [Maidstone, East Mill]

We can be fairly certain that the picks mentioned are the tempered and pointed metal picks used for shaping and dressing millstones. The use of the word ‘steel’ is interesting and confirms that the smith, who provided the tool for the miller to use, was using an alloy of iron with carbon and possibly other elements. The term ‘repair of the picks’ probably means sharpening them on a grindstone but they may have been re-hardened and tempered as well.

Similar is a Mill Bill, a tempered chisel for dressing millstones. The word ‘bill(s)’ is used twice in the Survey [Saltwood] but the context indicates that they do not refer to mill-bills – the true meaning here is elusive.

Gears/Cogs

‘ … cogs and rungs for the wheel ..’[Wimbledon]

‘ … copper bought for the cog-wheel ..’[Lambeth]

(many references to repair of cogs) [Bexley; Maidstone, East and West Mills; Wimbledon; Gillingham (both mills)]

In a medieval watermill the pit-gear (mounted on the horizontal wheel-shaft on the mill-side of the water-wheel) engaged with another gear having either radial pegs or a lantern wheel (having staves or bars set between two parallel wooden discs) mounted on a vertical spindle that engaged and drove the top millstone above.

In recent centuries the word trundle (see below) appears to relate generally to any gear having radial pegs rather than shaped rectilinear cogs for engagement. However, it is obvious that the word cog has much greater currency, both in modern and earlier times, as meaning any wooden element or tooth engaging with another gear. Thus in the survey a gear wheel is referred to as a ‘cog-wheel’ [e.g. Lambeth].

Rungs/Cross-bars/Trundle wheels

It is interesting to note that in most of the mills mentioned the driven gear, on the vertical shaft, took the form of a lantern gear. This is indicated by the use of the word ‘rungs’ [Wimbledon; Bexley; Maidstone, East and West mills] or ‘cross-bars’ [Gillingham (water and wind); Northfleet].

There is a distinct advantage in making the rungs of a lantern gear of iron, especially when the gear was relatively small with few rungs, where the engagement was more frequent and consequently the wear was greater. At Wingham Mill there is the item ‘ … repairing the trundle wheel and the smiths wages..’ which suggests that the rungs may have been made of iron, but all other incidences of ‘rungs’ or ‘cross-bars’ do not appear to relate to the smith’s work suggesting that all-wood lantern gears were more common.

‘Trundle wheels’ (in the plural) occur at Knaving (Reculver) and Northfleet watermills; ‘2 trendle-wheels and cross bars’ are mentioned both indicating two sets of millstones. We can be fairly sure that here two water-wheels existed, each powering one pair of millstones, which is the gearing arrangement that prevailed with vertical water-wheels throughout the Roman, Saxon and Medieval periods.

It should be noted that the word ‘wheel’ is used in the Survey for both the water-wheel and any gear, such that it is sometimes unclear which component they are recording.

Millstones

Millstones are specifically mentioned at a number of the mills [e.g. Wimbledon; Reculver; Barton; Saltwood; Bexley]. In all cases they are clearly newly-delivered, with the costs including transport. ‘… carriage and wharf dues..’ [Wimbledon]; ‘… for 2 millstones bought at Sandwich…and transporting the same... for carriage and bringing the same by water as far as Hythe and to the mill..’ [Saltwood]; ‘…for 1 millstone bought with carriage and wharfage …’ [Bexley].

The references to water transport indicate that the stones were brought from some distance suggesting an established trade, perhaps Peak District stones, from the north of England. The eye of the new stone was cut out after delivery; ‘… for making a hole in the same and setting them in place...’ [Saltwood]. Whether it was a bottom or top stone, a hole would be required to allow the millstone spindle to pass through, and a top stone would need a cavity for the mill rynd emplacement on the underside. The shape of the cavity for the mill rynd, whether a bar or winged rynd, probably varied from mill to mill.

Amongst the accounts there is no mention of the operation of dressing the millstones (but see notes above on the tools employed), indicating that it was a function normally undertaken by the miller and not the smith or a specialist journeyman millstone dresser. During their working life the millstones would have required periodic dressing.

New millstones would have required their grinding faces shaped and dressed according to the miller’s requirements. Most medieval millstones exhibit an inclined grinding face (bottom stone face convex, top stone concave) and it would be the miller who would generate the shape using a pick. The incidence of furrows in the millstones of thirteenth-century Kent is unknown but the existence of picks rather than chisels suggests that the surfaces were crudely generated by pointed picks only and probably devoid of furrows that prevailed in later periods. Each miller understandably adopted his own design of grinding face. At the eye of the stones a gap is required between the faces to admit the grain. The faces are shaped so that they run closer together away from the eye so as to crush and reduce the grain to meal and discharge it from the rim (skirt) of the stones. The miller would have prepared the roughness of the stone faces to facilitate the process of crushing, grinding and reducing of fine meal to suit his custom and practice. Different dressing arrangements may have prevailed for wheat, barley, oats and legumes.

Millstone Spindles

When a new pair or a bottom millstone is replaced, the position of the mill rynd within its emplacement cut into the underside of the top stone, moves up. This is simply due to the greater thickness of the new stones. If the bridge-tree, with its footstep-bearing supporting the vertical millstone spindle, cannot be raised, one way to facilitate the higher position of the mill rynd, is to lengthen the spindle. And so the evidence suggests:

‘ … for repairing and lengthening the mill spindle..’ [Harrow]

‘ … for lengthening the mill spindle..’ [Wingham]

At Saltwood where two new millstones were installed, ‘…lengthening of ... the shaft..’.

At Bexley the entry of a new millstone was followed by: ‘…for lengthening the mill shaft..’.

‘ … for lengthening the mill shaft…’[Westgate]

‘ … lengthening, enlarging and refurbishing to 2 mill-spindles..’ [Reculver]

Modern experience tells us that as millstones aged and became thinner the top stone became too light for effective grinding and was often repositioned in place of the bottom stone to continue to give service. Another reason for its move could be that as the grinding face wore away and the mill rynd cavity had to be deepened, the stone above the cavity became dangerously thin. If this was the prevailing life-cycle of a millstone, the new single stones at Bexley and Reculver would have been new top stones – why then lengthen the spindles? If they had been used as bottom stones, why not lift up the stone on wooden packing and continue to operate with the same length spindle?

One other possibility presents itself to explain the need for lengthening the spindles; a footstep-bearing made of iron or stone supported the bottom of the spindle. It is possible, depending on the bearing material and its lubrication, that the spindle end wore away in time, but it is difficult to believe that it wore to such an extent as to require lengthening, especially as there were alternative ways, as described above, of achieving adjustment.

Water-wheel

The word ‘wheel’ frequently occurs in the survey and it is used both for the water-wheel and the gears. A water-wheel is clearly the subject in the following examples:

‘ … for 2 bands for the wheel outside the mill..’ [Wimbledon]

‘ … for making two arms in the outer wheel..’ [Gillingham/Grain?]

‘ … for new making the outer wheel of the water mill..’ [Charing]

‘ … for 20 scoops for the same..’ [Charing]

In several other entries we can surmise that a water-wheel is again the subject because of the references to ‘scoops’ (buckets) or boarding, which would probably not occur on a gear wheel. Boards or boarding mentioned in context with water-wheels probably refer to sole-boards or shrouds [Northfleet; Maidstone]

‘ … repair of the wheel and its wooden casing…’ [Wingham]

‘ … 1 scoop for the same..’ [Gillingham, possibly Isle of Grain]

‘ … repairing ... the wheel and covering the same wheel with boards..’ [Westgate]

More than one water-wheel may have existed at some sites:

‘ … for covering the wheels of the mill before the gates (of Prelle) and at Dude Mill ..’ [Prelle and Dude, Wingham]

‘ … 200 nails for fastening scoops to the wheels..’ [Teynham]

‘ … for boards to cover the two wheels, 400 nails bought..’ [Northfleet]

‘ … covering the mill wheels with 4 boards..’ [Maidstone]

As pointed out above, the word ‘wheel’ is also used for a gear wheel. Some entries obviously refer to the gear mounted on the water-wheel shaft, called the ‘pit-gear’ in molinological terms.

‘ … 4 curved pieces of wood for the inner wheel..’ [Wimbledon]

‘ … making the inner wheel of the same mill anew..’ [Gillingham]

Other references to wheels apparently relate to the driven (trundle) wheel:

‘ … 2 wheels, cross-bars and cogs..’ [Isle of Grain]

Scoops

The word ‘scoops’ occurs in many entries and clearly refers to the buckets of a water-wheel [Charing; Maidstone; Northfleet; Gillingham; Isle of Grain; Teynham]. This suggests that breast-shot or overshot wheels prevailed but they may have used the term for wheels having radial paddles used with larger flows of water in river situations.

Sluice/Floodgate

The reference to a sluice confirms the presence of a water-mill:

‘ … making the sluice gates of the mill..’ [Croydon]

‘ … and the sluice of the same..’ [Isle of Grain?]

‘ … for covering the wheels of the mill before the gate (of) Prelle..’ [Wingham]

‘ … for sawing 200 boards at the floodgate..’ [Saltwood]

‘ … repairing the sluice of the bridge..’ [Northfleet]

Copper

‘ … copper bought for the cog-wheel..’ [Lambeth Manor]

‘ … 200 [blank] of copper bought for the same..’ [Wimbledon]

‘ … copper bought for the wheel..’ [Wimbledon]

‘ … 4 pieces of iron and copper bought for the wheel..’ [Wimbledon]

‘ … for copper bought for the beam and mill-shaft..’ [Westgate]

‘ … clearing the ditch around the smithy and the copper foundry..’ [Wingham, Harrow Mill]

The last reference suggests that a smithy and a copper foundry existed serving the archbishop’s manors. Considering the number of wind and water mills belonging to the archbishop, it is quite clear that their maintenance would have provided ample work for craftsmen (blacksmiths, carpenters, etc.) that the millers could have called on. In later centuries journeyman millwrights undertook such work especially when iron components, including cast iron, became more prevalent. In some of the mills we may imagine that basic maintenance, e.g. dressing the millstones, adjustment of bearings and perhaps the incidental and minor repairing of cogs and waterwheels, was undertaken by the miller himself. It would be an inducement, of course, to keep up production and minimise shut down of the machinery and for the miller to be observant and anticipate operational problems and deal with them himself. Breakdowns causing the mill to stand idle whilst a message was dispatched to the smith or carpenter were to be avoided.

The use of copper in these mills is intriguing. In later centuries the metal work and components found in both wind and water-mills was almost wholly wrought iron or cast iron, and copper is rarely met with. It occurs very occasionally as bearings alongside brass and other bearing alloys. Its most likely use in medieval mills would be for the bearings that supported the wind-shaft of a windmill, or the wheel-shaft of a water-mill. In the foundry the copper would have been cast as a half bearing made to the diameter of the iron journal or wood shaft that it carried.

One other bearing exists in both wind and water-mills at the bottom of the millstone spindle, called a footstep bearing. In Roman, Anglo-Saxon and later periods this bearing often took the form of a hard stone or a small plate of iron, which carried the lower end of the iron, or iron shod, vertical millstone spindle. A soft metal such as copper is less likely to have been used where the bearing area is small, such as the point load of the millstone spindle.

Canvas

The following article on the earliest Kentish windmills details the Kilwardby references to canvas in the construction of windmills. Our current knowledge of early medieval wind-mills is very limited and greatly influenced by the oral traditions and scant remains of much later mills. As far as we are aware the traditional cloth-covered sails have always been made from a single manufactured piece of cloth to avoid the weakness of stitched joints. The various references to ‘ells of canvas’ varying from 12 to 44 ells, may therefore be taken indicating the total length of the sails. (An ‘ell’ of fabric was approximately 45 inches.) Although medieval iconography would suggest that many wind-mills had four sails, variations probably occurred. Some millers may have sought to replace only part of their canvas and others may have purposefully stored reserves of the material in readiness for storm damage. We should remember that these early mills depended upon the miller having ‘a weather eye’ to avoid catastrophic damage by turning the mill into the wind.

From the survey the following Kentish mills can be identified:

Manor Name Type Feature(s) Page ref.*

Gillingham water ‘scoops bought for the water mill’ 37

Gillingham wind ‘canvas for the sail of the windmill’ 37

Isle of Grain water ‘outer wheel’; ‘sluice’; ‘wharves’ 37

Teynham wind? ‘hook beam’ 48

Teynham water ‘wharfs round the mill’; ‘scoops to

the wheels’ 52

Westgate water ‘wharfs round the mill’; ‘scoops to

the wheels’ 61

Reculver wind ‘2 sails’ 68-9

Hythe ?

Dreystedel ?

Knaving ?

Barton ?

Manor Name Type Feature(s) Page ref.*

Wingham Dude water ‘wharf’; ‘covering the wheels of the

mill before the gate (of Prelle)’ 78

Wingham Prelle wind ‘canvas for the sails’

Wingham Harrow water? ‘wall next to the mill’

Wingham Barton water? ‘repair of the wheel and its wooden

casing’ 88

Aldington wind 96

Bishopsb’ne wind ‘canvas’ 111

Petham wind ‘canvas bought for the sail’ 117

Lyminge wind ’44 ells of canvas’ 123

Saltwood water ‘cleaning the water course of the mill’;

‘at the floodgate’ 128

Otford water? 133

Bexley water 146

Northfleet water ‘scoops’; ‘boards to cover the

2 wheels’; ‘sluice’ 153

Maidstone East water ‘scoops’; ‘covering the mill wheel

with 4 boards’ 160-1

Maidstone West water? ‘weir’ 160-1

Charing water ‘outer wheel of the mill’; ‘for

20 scoops of the same’ 167

Boughton under Blean Horell ? 173

* See the Kilwardby Survey published on the KAS Website.

robert spain

the earliest kentish windmills

Kealey’s book on England’s twelfth-century windmill pioneers provides a comprehensive account of the introduction of this new type of mill.1 The earliest documented windmill in England – at Wigston Parva in Leicestershire – was apparently in existence by 1120. Kealey has compiled a list of 56 English windmills documented by c.1200, of which seven were in Kent:

|

Location |

Date |

Owner |

|

Romney |

1190 |

Romney Hospital |

|

Reculver |

1195 |

Eastbridge Hospital |

|

Westhalimot (Thanet) |

1195 |

Eastbridge Hospital |

|

Monkton |

1198 |

Christ Church Priory |

|

Canterbury environs |

c.1200 |

Eastbridge Hospital |

|

Canterbury environs |

c.1200 |

St Augustine’s Abbey |

|

Chislet |

c.1200 |

St Augustine’s Abbey |

There is slighter evidence of two other early windmills at Lenham and Charing.

Seventy-five years later, the Kilwardby Survey (see pp. 107-28, and the preceding article) mentions purchases, usually of canvas, required for the repair of windmills on seven of the archbishop’s sixteen Kentish manors:

‘ … 24 ells of canvas for the sails of the windmill …’ [Gillingham]

‘ … [timber for] two sails …’ [Reculver]

‘ … 42 ells of canvas for the sails of Prelle mill …’ [Wingham]

‘ … 1 rod bought for the windmill …’ [Aldington]

‘ … 24 ells of canvas for the sail …’ [Bishopsbourne]

‘ … 12 ells of canvas bought for the sail …’ [Petham]

‘ … 44 ells of canvas [acquired] …’ [Lyminge]

A decade later the Pecham Survey reveals that 10 of the archbishop’s manors in Kent possessed a total of 17 windmills.2 These surveys of the archbishop’s manors in 1273-4 and 1283-5 thus provide sound evidence of the spread of windmills since their first appearance in Kent in the last decade of the twelfth century.

No doubt other Kentish landholders also introduced this new type of mill. Thus from fewer than ten examples in 1200 the number of windmills in Kent had grown substantially by the end of the thirteenth century.

terence lawson

1 E.J. Kealey, 1987, Harvesting the Air: Windmill Pioneers in Twelfth-Century England, Boydell / University of California Press. The author makes a strong case for the invention of the windmill in Western Europe, most likely in England, thus discrediting the traditional view that the idea stemmed from reports by returning crusaders of such mills in the Holy Lands. He devotes a whole chapter to the early Kentish windmills.

2 K. Witney, 2000, The Survey of Archbishop Pecham’s Kentish Manors 1283-5, Kent Record Series, vol. xxviii, KAS, Maidstone.

geophysical survey and evaluation trenching at queenborough castle, isle of sheppey

In August and September 2005 geophysical survey and evaluation trenching was undertaken on the site of Queenborough Castle (NGR 59122 17216) by Channel Four’s Time Team television programme. The fieldwork comprised geophysical survey of the castle mound followed by the excavation of six targeted evaluation trenches of varying dimensions.

Following the Norman Conquest, the Isle of Sheppey was split into separate manors with the area of Queenborough becoming part of the manor of Rushenden until the founding of the castle and the town in the mid fourteenth century. Although Queenborough itself was not founded until 1368, a small settlement, called Bynne or Bynnee, derived from the Old English binnan ea, meaning ‘within the river’ and probably referring to a site at the western end of the Swale, appears to have existed here from the Saxon period. The town charter of 1368 described Bynnee as a ‘little hamlet of fishermen’s houses’.

In 1361 Edward III purchased land belonging to the manor of Rushenden on which a castle was to be built for the ‘defence of the realm’ (Woodruff 1897, 170-2). At least two houses, those of Simon Waryn and John Segar, were demolished to make way for the building (Beresford 1967, 459). While the castle was clearly built primarily as a defensive structure, the years 1360-1369 were a time of truce during the Hundred Years’ War and other factors, such as providing a royal refuge, perhaps from the black death, which was ravaging the country at the time, could have been secondary considerations. In a charter of 1368 the village of Bynnee was formally replaced by the Royal Borough of Queenborough, which was laid out to accompany the castle and was named after Edward’s wife, Philippa of Hainault.

Queenborough is the only deliberately planted town of this period in England and included an organised arrangement of the castle itself, tene-ment plots, a church, a harbour, a watermill, a market and a market house. Although the church represents the only upstanding remains from Edward III’s medieval town, the 1864 1st edition 25in. OS map suggests that many of the plots off the High Street retained their medieval boundaries. Most of the existing standing buildings date from the eighteenth century, although the façades may conceal remnants of earlier buildings within. Records of building work associated with the construction of the new town appear in the castle accounts from 1366 onwards, suggesting that it was already under construction before the charter was granted. In 1368 Edward III transferred the wool staple from Sandwich to Queenborough, hoping to encourage more people to live in his new town. For the next ten years Queenborough expanded rapidly, but when the staple was returned to Sandwich in 1378 Queenborough no longer thrived, reverting to a population of fishermen, oyster dredgers and boatmen; the town, however, retained its borough status (KHTS 2004).

Although very little of the castle remains, even as earthworks, there is a wealth of documentation relating to it, largely because it remained a royal castle throughout its active history. The castle is fully documented in various exchequer accounts and records, particularly the Calendar and Pipe Rolls. Construction of the castle began in 1361 with up to 1,600 workers, including masons, carpenters, smiths, carters and labourers, under the control of a master mason, John Box, and was completed c.1367. The castle, the only wholly new Royal castle built in England during the later medieval period, was constructed to a new, concentrically circular design, anticipating the centrally planned artillery castles of Henry VIII, built nearly two hundred years later. It was also probably one of the first castles to be designed to house artillery; in 1365 ‘two great guns and nine small ones’ were supplied to the castle from the Tower of London (Tout 1911, 675) although the castle accounts also refer to the construction and use of stone-throwing engines and trebuchets within it.

The castle comprised a large circular rotunda with six external turrets or towers around a central court with a well in the centre. The rotunda was enclosed within a circular curtain wall with a gatehouse, probably to the west, and a postern gate to the east, all enclosed by a large moat. The entrance to the central rotunda was on the eastern side, the opposite side to the main entrance into the outer court. Open walled passageways linked the outer gate and postern to the central rotunda, dividing and blocking the outer court, so that in the event that the outer ring wall or gatehouse was breached, attackers would be forced to move halfway round the circumference, exposed all the way to fire from the central rotunda (Allen Brown 1954, 135). Two masonry buildings also seem to have been built in the outer court between 1369 and 1377 (Allen Brown et al. 1963, 798), although their function is uncertain. Military capabilities aside, Queenborough Castle, like other medieval castles, was also a residence. The central rotunda contained residential apartments, including a large hall and other accommodation considered appropriate to a royal residence. From its completion the castle was one of a small group of residences to which the king’s movements were increasingly confined as he grew older and the frequency of his visits is apparent in contemporary records (ibid., 802). The castle was attacked only once during its life, during the Jack Cade rebellion of 1450, when Sir Roger Chamberlayne and his small garrison successfully defended it.

The supply of fresh water appears to have been a problem as no local spring could be found. Barrels were provided to catch rainwater channelled through lead pipes within the confines of the castle. However, in 1393 one Robert Weldyker was paid £10 for sixty weeks work digging a well.

Following a period of prosperity immediately following its founding, the town of Queenborough’s fortunes began to decline due to competition from the more accessible ports of Rochester and Chatham. By the mid-seventeenth century, the relevance of the Swale as a shipping route waned and Queenborough’s fortunes had declined further with the development of Sheerness. The town’s fate was sealed in 1650 when the Commonwealth government decreed that the castle was obsolete and it was destroyed. Fortunately a plan of the castle, probably of Elizabethan date, survives in a manuscript held at Hatfield House (Allen Brown et al. 1963, 795). A lost engraving by W. Hollar, dated 1610 and reproduced in an eighteenth-century copy, depicts the castle in the early seventeenth century. The Parliamentary Commissioners who surveyed the castle in 1650 also produced a detailed description (ibid.). The castle was sold the same year and demolished.

Very little remains of the castle today other than a few low earthworks. The railway line to Sheerness cut through the eastern side of the mound when it was constructed in the 1860s and a pump-house was built over the former castle well to provide water for the steam engines. In the 19th century also, a school was built over the western side of the castle; it is now used as a community centre and library. Most of the surrounding area has been developed for housing in recent years.

Geophysical Survey

The castle site was investigated using a combination of resistance survey (Geoscan RM15 resistance meter), Ground Penetrating Radar (Pulse EKKO 1000 GPR unit with a 225MHz frequency antenna) and magnetic survey (Bartington Grad 601-2 fluxgate gradiometer). The results were interpreted via a combination of GSB and commercial software.

Ground conditions were moderate to good for data collection; most of the area had a relatively short grass cover and was free of obstructions. However, the centre of the survey area contained two wells which had been capped and covered by a raised rectangular brick and concrete platform measuring 15m x 12m. Generally the quality of the resistance data was good, allowing identification and interpretation of the suspected archaeological features; however, the ground conditions were extremely dry which did hinder probe contact.

Evaluation Trenching

In total, six evaluation trenches were excavated over a three-day period. Only three possible medieval features; a short, rather irregular length of gully and two small, irregular scoops or hollows, were located during the evaluation. All three of the features were in Trench 2. The gully, some 0.50m wide and 0.30m deep, produced pottery, broadly datable to the twelfth to mid-thirteenth century, along with small quantities of animal bone, a single fragment of window glass and an iron musket ball. Immediately to the north of the gully were two shallow, irregular features containing a similar dark grey fill but no datable artefactual evidence. These three features are assumed to be broadly contemporaneous, although the presence of the iron musket ball suggests a later date than the medieval pottery recovered.

The remains of the castle are represented by a series of large robber trenches which also relate to the mid seventeenth-century demolition of the castle and subsequent salvage of the building materials. Only very small areas of in situ masonry foundations were recorded.

The 1650s demolition and salvage would have left the area scarred with large, partly filled robber trenches, some over 2m deep. Deposits of London Clay and rubble lenses were subsequently deposited over the whole of the mound. Other features and deposits recorded relate to the now demolished Victorian pump-house constructed above the castle well to provide water for the railway, the modern capping of the well-head and the landscaping of the mound undertaken by the local council in the 1970s.

finds

Pottery

The recovered pottery assemblage is very small, comprising only 21 sherds. Of this, 16 sherds were medieval and five post-medieval. Medieval wares include shelly, sandy/shelly and sandy wares, all probably originating from source(s) in north-west Kent. The six post-medieval sherds comprise coarse redwares, not closely datable and modern stonewares recovered from the topsoil.

Ceramic Building Material and Fired Clay

The ceramic building material includes fragments of brick and roof tile. None of this material was recovered from in situ structural elements, and most instead derived from robber trenches, and levelling or demolition deposits.

Stone

This category consists mainly of building material, and includes two fragments of moulding and two pieces with surviving flat tooled surfaces. Two other pieces of worked stone were recovered from topsoil in Trench 1; both are fragments of shot of very similar size and appearance (possibly both from the same ball). Both fragments are of even shape and well finished by pecking; the ball(s) was of 170mm diameter (6¾in.), and had an original weight of approximately 10kg (22lb). This type and size of ball could have been fired from a wrought-iron gun (late fourteenth to late sixteenth century), or from a perier (fifteenth to seventeenth century). Interestingly, stone shot recovered from the Mary Rose (1545) includes a number of pieces of similar size, designed to fit wrought iron guns known as ‘port pieces’. The majority of these items were made of Kentish Ragstone, quarried in the Maidstone area (J. Gardiner, pers. comm.).

Coins and tokens

Five coins and tokens were recovered (four copper alloy and one lead). Two of the copper alloy coins were recovered unstratified from Trench 1. One is probably a post-medieval half penny, too worn and corroded for closer identification, and the second is a farthing of George V (1920).

The other three objects were unstratified in Trench 3. The first is a jeton, probably minted in Paris or Tournai during the reign of Louis XI (1461-1483) or his successor Charles VIII (1483-1497) (see Mitchener 1988, no. 580 and 581). The second is a crude lead token comprising a circular flan bearing the letters H W above O(?) B W on the obverse. The lettering is poorly executed, but presumably represents the name of a tradesman. The third object is too badly worn and corroded to be closely identified, and may not even be a coin or token.

Silver and copper alloy

A silver cufflink was recovered from Trench 3 topsoil. Apart from the coins and tokens, copper alloy objects comprise four buttons, four buckles, a small decorative fitting, a cutlery handle, and miscellaneous sheet/strip/bar fragments; all are demonstrably or probably of post-medieval date.

Iron and Lead

Ironwork consists almost entirely of nails and other structural items, although one musket ball was recovered. A lead musket ball can be added to the iron example and other objects (apart from the two tokens: see above) include two window came fragments.

Discussion

Very little of the original fabric of the castle remains, with only small areas of in situ masonry foundations surviving within the robber trenches. However, the robber trenches themselves preserve the ground plan of the castle, although evidence for repairs, alterations and function is likely to have been severely compromised, if not totally destroyed.

The ringwall of the castle appears to have had an internal diameter of approximately 84-85m and the internal diameter of the central court appears to have been around 16-17m. The diameter of the central rotunda is more problematic, but a diameter of approximately 38-40m is suggested, with the six towers extending approximately 6m beyond this. When compared to the physical remains of the castle recorded during the course of the evaluation, the thickness of the ringwall depicted on the Hatfield MS plan appears rather greater than the remains indicate, suggesting that while this plan is broadly accurate, some elements of it may have been exaggerated.

The locating of the foundations of an apse-like feature which appears in the central court and the two parallel walls, probably representing a passageway between the rotunda and the postern gate on the Hatfield MS plan indicates that the main gate of the castle was to the west, facing down the High Street of the town and the postern gate to the east. Although not investigated, the parch mark seen on several aerial photographs of the site is, according to local knowledge, the site of a Second World War air raid shelter and is unlikely to represent the site of the gatehouse.

Later demolition and robbing has probably destroyed all evidence of function within the various elements of the castle. It therefore appears that documentary records are more likely to produce evidence for function than archaeological excavation.

The evaluation has confirmed the general accuracy of the Hatfield MS plan, although the thickness of the ringwall appears to have been slightly exaggerated on this. This interpretation appears to be supported by the results of the earlier evaluation within the car park (Pratt 1991), where the moat was located, but slightly closer to the centre of the mound than was expected.

The recovery of two fragments of a stone ball or balls from the topsoil in Trench 1 is significant. There is documentary evidence for cannon being supplied to the castle from the Tower of London in 1365 and for the presence of an artillery specialist (valettus artillerie), John Arblaster, at Queenborough between 1373 and 1375 (Tout 1911, 675 and 682). Although these finds may represent ammunition for other devices, such as catapults and trebuchets, the stone appeared very carefully worked into a sphere, which would have been required for a cannon ball, but not necessarily for catapult or trebuchet projectiles. The report of the Parliamentary Commissioners of 1650 stated that the castle was unsuitable for artillery; however, it may be that emplacements built for fourteenth-century cannon were too small, or too weak, to house the larger and more powerful cannon of the seventeenth century.

vaughan birbeck and rob armour chelu

references

Allen Brown, R., Colvin, H.M. and Taylor, A.J., 1963, The History of the Kings Works II, HMSO.

Allen Brown, R., 1954, English Medieval Castles, Batsford.

Beresford, M., 1967, New Towns of the Middle Ages, London, Lutterworth Press.

KHTS 2004, Kent Historic Towns Survey: Queenborough. English Heritage and Kent County Council.

Mitchener M., 1988, Jetons, Medallets and Tokens Vol. 1 Mediaeval Period & Nuremberg, Seaby.

Pratt, S., 1991, ‘Queenborough Castle: Report on Evaluation Trenches’, Canterbury Archaeological Trust, unpubl. client report.

Tout, T.F., 1911, ‘Firearms in England in the Fourteenth Century’, English Historical Review XXVI, 666-702.

Woodruff, C.E., 1897, ‘Notes on the Municipal Records of Queenborough’, Archaeologia Cantiana, xxii, 169-85.

captain george gooch, the first resident at fort house, broadstairs

Fort House stands in a prominent position overlooking both the sea and the town, and is better known as Bleak House, on account of its connection with Charles Dickens who on occasion stayed there in the 1850s. In the intervening years the building has been enlarged, and has acquired a crenellated appearance. An article by W.H. Lapthorn1 states that Fort House was built in 1801, as the private residence of George Gooch, ‘the first commander of a large fort known as North Cliff Battery (the ruins of which can still be seen in front of the house)’.

Captain Gooch’s residence at the property in 1805 is further referred to by Lapthorn in an account of the return to England of Admiral Nelson’s body aboard HMS Victory, which briefly dropped anchor off Broadstairs in mid December. He writes, ‘as a mark of respect to the nation’s fallen hero, Captain Gouch ordered the flags to be lowered on the staffs at Bleak House and the fort. He also instructed the gunners to fire one gun every minute, which was done forty-seven times – a gun for each year of the life of the famous seaman’. The source material for this tribute to Nelson is unfortunately not recorded.

By 1805, Gooch would have been aged forty-four, and he could claim by then to have seen much of life. Born in 1761 in Great Yarmouth, the second son of Samuel and Sarah, he had been apprenticed as a mariner to a relative of his mother’s, George Plowman, and to a William Palmer.2 His apprenticeship began at the age of fourteen, and he was indentured for seven years. At this time trade from Great Yarmouth was extensively with Germany and the Baltic countries, as well as with Norway; and Gooch was certainly apprenticed in the Baltic and Hamburg trades.3

In or about 1780 Gooch joined the service of the Honourable East India Company, as a maritime officer. Such a career could offer potentially great rewards, and could set an individual up for life, as the Company was responsible for all trade, administration and military matters in an ever expanding British India. In 1780-81 Gooch served on The Chapman, one of the Company’s ships, as a Fifth Mate and thereafter he was promoted to Second Mate, and then as a First Mate, on the Lord Camden. This took place between the years 1783-1794. By 1795 Gooch was further promoted to the rank of Captain, on board the Sir Stephen Lushington, on which he served from 1795 to 1803. By 1803 he had become the Principal Managing Owner of the ship.

Throughout this twenty-year period or so, Gooch initially voyaged between England and Bombay but he travelled more extensively to the eastern, Coromandel coast, and the Bay of Bengal. This would have taken in ports such as Madras, Masulipatam and Calcutta where his cargos might have included items such as tea, camphor, cassia lignea, rattans, arrack and white pepper. As an East India Company Officer, Gooch, aside from his salary, would have enjoyed the additional privileges that extended to all officers by way of a ‘private trade’. This enabled Company officers to reap a good income by taking English goods out to India or China, and to return with Eastern goods for which there was a ready market.4

Some time in 1798 Gooch married an Amelia Kerrich from his home County of Norfolk, and this occasion was recorded in the Gentleman’s Magazine.5 It would seem that by 1804 or thereabouts, he ceased service with the Company, and his career became more focused at home, possibly on account of family matters.

On 5th July 1804 he was elected to the Trinity House Corporation as a Younger Brethren.6 The significance of this is that the Corporation was the chief pilotage authority for the country, with amongst other things responsibility for the lighting and marking of British coastal waters. Whilst the work of the Brethren was largely supervised by a Board of ten Elder Brethren elected for life, younger members, of whom there were about three hundred, comprised of mainly Merchant Navy Captains and a small number of Royal Naval Officers.

Aside from his residence at Fort House, Gooch also lived at a property in Brunswick Square, in Bloomsbury, located close to Coram’s Fields and St Pancras. His first noted connection with this property is recorded in 1804, at the time of his election to the Trinity House Corporation. In March 1805 his first daughter Emily Sarah was born at the London home, and this was followed shortly thereafter by the birth of a second daughter, Georgiana, in the following July. Tragically for the family, the girls’ mother died some eight months later in February 1807, at the age of thirty-five. Amelia was buried at her in-laws local church, St Mary’s, in Beaconsfield, and a marble monument sculpted by William Tollemarche was erected on the south wall to her memory, depicting two girls weeping over an urn mounted on a pedestal beside which is a withered tree.

Gooch was now left with two very young children to bring up, and to assist himself he enlisted the help of his sister, Sarah, who was, and remained a spinster throughout her life. In fact, Sarah remained an influence throughout the girls’ lives, and at the time of the 1841 census she was living with Georgiana and her husband, at Gunton Hall, in Norfolk, by then aged 76.

On 19th March 1818, Gooch was elected as an Elder Brethren, following the death of Captain Sir William Fraser,7 and he remained a member of this select group until his own death fourteen years later. During this period Gooch appears to have been very much an active Elder Brethren, a position which was not without its financial rewards.8

Aside from maintaining his London residence, Gooch and his family lived at Broadstairs. The Overseer’s Accounts (an early form of rates) in 1822 for St Peter’s Thanet,9 confirms Gooch’s continued residence at Fort House. Within these records, it is apparent Captain Gooch rented out nearby stables situated part way between Fort House and the Tartar Frigate, a tavern, to a Thomas Penfold, presumably the publican. The Tartar Frigate is still a public house today.

An entry in Pigot’s Directory for Kent, 1828/29, further establishes Gooch’s connection with Fort House, under the heading of ‘Gentry and Clergy’, and Sarah Gooch’s connection with the area is confirmed by her ownership of a number of plots of arable and pasture land,10 variously described as ‘Cliff Field’, ‘Chapel Field’, and ‘The Three Acres’, which were rented out.

In May 1831, Gooch attended as a witness the marriage of his eldest daughter, Emily, at St George’s in Bloomsbury, to a young clergyman named Thomas Vincent Fosbery. He was not, however, to witness the marriage of his second daughter, Georgiana, to Robert Fowler of Gunton Hall, a some time Captain in the East India Company, which took place in 1835.

The Kentish Gazette for 24 July 1832 carried a brief obituary for Gooch in the following terms: ‘Jlly 16th, at Broadstairs, on Monday July 16th in the 72nd year of age, Capt. George Gooch, an Elder brother of Trinity House’. Gooch was buried at St Peter’s, Thanet, and his memorial recorded his life as follows:

Sacred to the Memory of Captain George Gooch

Late of the East India Company’s Service

And an Elder brother of the Trinity House

Esteemed in public beloved in private

The Friend of the friendless

And a humble believer in Jesus

Who departed this life

In a simple reliance on the merits of his Redeemer

And full of a glorious life

July 16th 1832 aged 71

Blessed are the dead which die in the Lord

Gooch’s lengthy Will appointed four executors, including his sister Sarah, and a clergyman named Walter Kerrich as the executors, and effectively divided the estate equally between his two daughters. The net residue of the estate at the time of its full declaration in 1835 amounted to some £21,197, a considerable sum.11

daniel darwish

1 W.H. Lapthorne , ‘Bleak House – The First Maritime Museum in Thanet’, Bygone Kent, vol. 2, no. 1 (Jan. 1981), 3-7.

2 A Calendar of the Freeman of Great Yarmouth 1492-1800, Norfolk & Norwich Archaeological Society, 1910.

3 A. Farrington, A Biographical Index of East India Company Maritime Service Officers, 1600-1834, British Library, 1999.

4 In the case of a Commander of a ship of 755 tons and above, the allowance was as much as 56 tons or 20ft of space; E. Keble Chatterton, The Old East Indiamen, 1914, p. 227.

5 The Gentleman’s Magazine, 1798, Volume 68, Part 2, p. 1148.

6 Guildhall Library, Aldermanbury, London, Manuscripts Section (Ms 30324).

7 Ibid. (Ms 30302). Gooch had previously been a candidate for Elder brother in January 1816 (Ms 30306/1).

8 A search of the Minutes of the Corporation of Trinity House reveals the following appointments: April 1818, appointed to the Ratcliff Book; May 1819, appointed to the Committee of Examination; June 1823, appointed to attend an Admiralty Court hearing in the High Court (as one of two Elder Brethren Assessors); May 1824, nominated to be elected Nether Warden; Jan 1826, appointed to the House Committee; June 1826, elected Rental Warden; May 1827, Junior Supervisor of the Ballast Office; and to the Committee of Pensioners; July 1827, elected Deputy Warden (April 1828 reported on damage to the groynes at Reculver); May 1828, appointed Senior Member and Chairman of the Committee for Collections; June 1829, elected Younger Warden; May 1831, appointed Supervisor of the Ballast Office; appointed Senior Member of the Committee for Lights.

9 Overseer’s Accounts 23 March 1822, St Peter’s, Thanet. Information kindly provided by Mr Peter Ewart of the Canterbury Cathedral Archives.

10 Tithe apportionment for St Peter’s, Thanet (1842).

11 The equivalent of approximately £1,350,000 today.

Fig. 1 Site location, plan of the excavation and evaluation trenches and detail of Area 2. Note: the mapping used in Fig 1 is reproduced by permission of the Ordnance Survey on behalf of the Controller of Her Majesty’s Stationery Office, Crown Copyright.

Fig. 1 Queenborough Castle, showing locations of evaluation trenches

Captain George Gooch

PLATE I

PLATE II

Fort House, Broadstairs

PLATE III

Fort House, Broadstairs